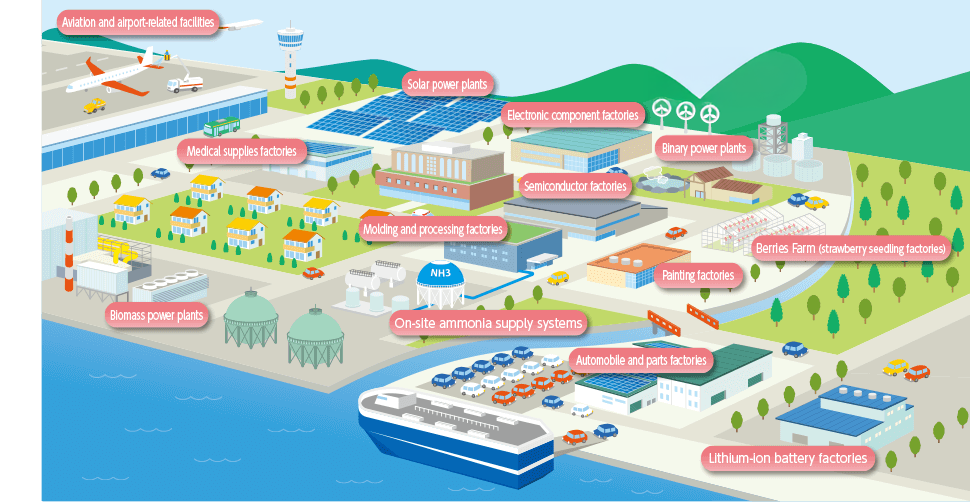

Efforts to Reduce Environmental Impact

Among all the types of industrial machinery we handle, we are strengthening our efforts to expand sales of products that contribute to resource recycling, resource conservation, and reduction of workload and workforce in our customers’ product manufacturing. The variety of environmentally friendly products has been increasing year by year, and in recent years, many of them have become useful for social infrastructure. The DJK Group considers the provision of products and services to be a contribution to society through business, and will continue to expand the range of products it handles, recognizing that environmental friendliness is the most important issue in business.

Business areas for environment-related products

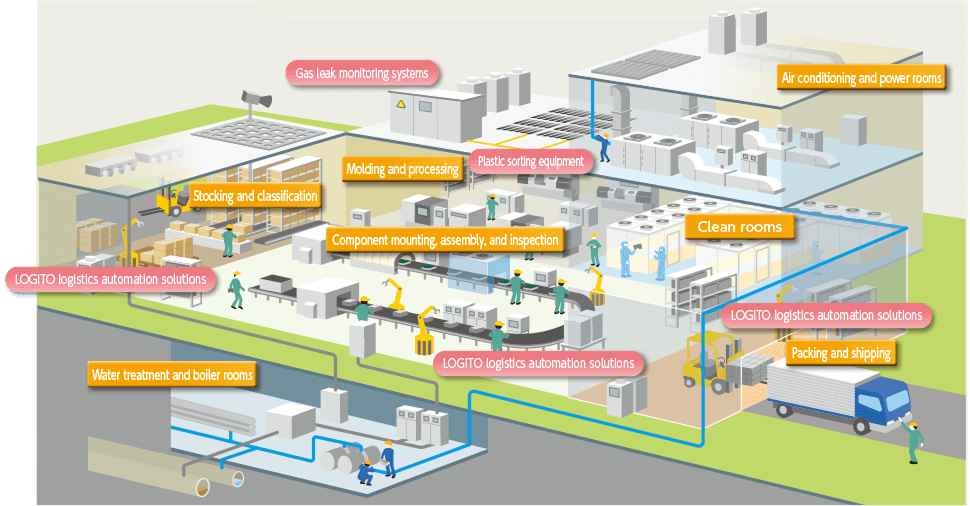

Business areas for environment-related products (inside factories)

RE100 Solutions

Initiatives for Plant Safety and Maintenance

To address social challenges such as aging plant equipment and labor shortages, we are working to build smart factories and maintenance systems that make effective use of cameras, sensors, and other technologies.

We handle gas leak monitoring systems manufactured by Konica Minolta, Inc. By using these cameras instead of conventional gas detectors for gas leak inspections, it becomes easier to identify the source of leaks and detect abnormalities in high or hard-to-reach areas. The system also enables visualization of gas accumulations from volatile solvents and other hazards in work environments, contributing to improved working conditions and accident prevention.

We are actively promoting the adoption of these systems not only at plant facilities but also at fuel depots, tankers, and a wide range of manufacturing sites.

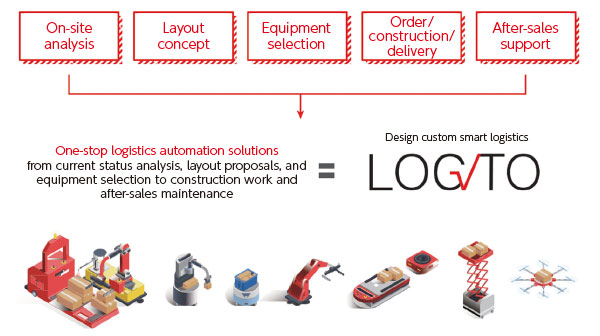

Contributing to Sustainable Industrial Development through LOGITO

To address the declining workforce in the manufacturing industry, we have launched the “LOGITO” brand, offering logistics automation solutions aimed at achieving automation and labor-saving operations at manufacturing sites, factories, and logistics warehouses.

Engineers with a wealth of field experience select the optimum equipment from among various manufacturers all over the world and propose custom designs to realize high-cost performance. We provide one-stop solutions, from factory analysis to layout proposals, equipment selection, construction, and after-sales service.

By promoting workforce reduction and labor saving at production sites, factories, and so forth, we will contribute to the sustainable development of industry in various aspects, including productivity, efficiency, and consideration for the environment.

Joint Crediting Mechanism (JCM) Business

This is a mechanism used in order to quantitatively evaluate contributions of Japan to greenhouse gas emission reductions and removals which are achieved through the diffusion of, among others, leading decarbonizing technologies as well as through the implementation of measures in developing countries and others, and in order to use such contributions to achieve Japan’s nationally determined contribution (NDC).

Adopted Projects

FY2018

| Project |

Project Introduction of a biomass boiler in a chemical plant |

| Expected GHG* reduction |

16,882t-CO2 per year |

FY2021

| Project |

Total 28MW solar power generation project utilizing the PMGD Scheme |

| Partner country |

Chile |

| Expected GHG* reduction |

24,115t-CO2 per year |

Sustainable Strawberry Production

Daiichi Jitsugyo Berries Farm

(Moroyama, Saitama)

At Daiichi Jitsugyo Berries Farm, a company-owned facility, we contribute to the conservation of biodiversity by efficiently mass-propagating strawberry mericlone seedlings in a short period of time using an advanced liquid culture system.

Grown in a clean environment within a closed-type plant factory, the seedlings have minimal exposure to pathogens, which significantly reduces the need for agricultural chemicals. The facility also enables the preservation of new and original varieties, playing an important role in safeguarding the genetic diversity of strawberries.

In addition, the farm achieves net-zero CO₂ emissions through the use of carbon-offset electricity.

Other Environmental Initiatives

For company vehicles used in Japan, the ratio of environmentally friendly vehicles, including hybrid vehicles, is over 90%.

In addition, in the office environment, we are promoting paperless meetings, and using web conferencing systems to reduce greenhouse gas emissions from business trips.

We are working to expand green procurement by prioritizing the use of Eco Mark certified and recyclable products for office consumables and environmentally friendly inks and paper materials for booklets and other publications.

We believe that the accumulation of such steady efforts can also contribute to environmental conservation, and we will continue to promote internal efforts to reduce the burden on the environment.

Eco-friendly cars

Promotion of web conferencing

Going paperless

Green procurement